RFID stands for Radio Frequency IDentification.

RFID stands for Radio Frequency IDentification.

RFID is an abbreviation that refers to any electronic device that uses radio waves to facilitate the communication of data for the purpose of identification, and sometimes to locate and/or sense the condition(s), of animate and inanimate objects."

Anything that communicates using radio waves needs to be able to identify and differentiate itself from other things.

The RFID Network produced a short video (above) that shows different kinds of RFID devices and how RFID works. This video was a part of our pilot cable television show.

The first use of RFID was in the 1940’s to identify and differentiate military aircraft. It’s what allowed the allies to determine which plane was a friend and which one was not. Today, RFID is still used by the military, as well as commercial airplanes.

RFID is also used by numerous other things:

- The keys to open your car door;

- The automatic payment passes used in toll booths;

- Building access systems;

- Passports, payment cards, and even student ID cards;

- Wireless sensors and mesh networks.

Laptop and tablet computers, as well as music players and other devices that connect to wireless networks use a unique identifier called the Media Access Control or MAC address. Bluetooth devices such as the headset for your mobile phone also use this method for wireless identification.

The EAS or Electronic Article Surveillance tags you see on clothes in retail stores are NOT RFID, even though the word “surveillance” implies they are. EAS tags don’t uniquely identify an item, they only identify if the item it is attached to has been paid for or not.

But the most common device that uses Radio Frequency Identification is your mobile phone. The International Mobile Equipment Identity or IMEI uniquely identifies a specific mobile phone being used on a mobile network.

In fact, smart mobile phones such as the iPhone and Android-based phones use multiple different Radio Frequency identifiers: an IMEI and MAC addresses for both 802.11 WiFi networks and a different one for Bluetooth communication.

There are many different types of devices that identify themselves using radio communication and it’s easy to get them confused. There’s no need to be concerned if you don’t’ understand the differences, just remember that RFID only provides a unique wireless identification for objects. Without these different kinds of RFID, there could be no wireless networks because there would be no way to know the difference between two different wirelessly connected objects.

Radio Frequency Identification (RFID) and wireless RF sensors are the conduit between the physical world and the digital world because it allows physical objects to be identified and differentiated by computers. These technologies provide the ability to identify, locate, and sometimes sense, the conditions of animate and inanimate entities and their surrounding environment, and enable real-time decisions to be made based on that information.

UHF RFID : ISO18000-6C and GS1 standards

This in-depth article is focused on one specific kind of RFID technology: UHF RFID. More specifically, RFID defined by the ISO18000-6C and GS1 standards. This is the technology used by retailers and the government to locate and track items. UHF RFID is changing the way companies do business. Cutting through all the hype, the basic business benefit of UHF RFID technology is improved asset visibility. There is no company in the world that cannot profit from having a more accurate picture of what it has and where it’s located.

This in-depth article is designed to help you implement UHF RFID technology successfully. Our goal is create a resource for everyone that wants to understand:

- what is UHF RFID technology;

- where and why they would use UHF RFID technology,

- and how to implement UHF RFID technology successfully.

To get started, everyone should have a basic understanding of a UHF RFID system that uses these standards. There are four basic components to every UHF RFID system:

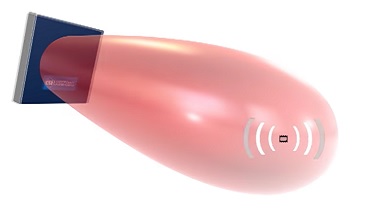

1) RFID Tags

RFID tags are affixed to assets. Each has a unique numerical identifier so differentiation is possible. It is common for the RFID tag IDentifier to contain the Serialized Global Trading Identification Number (SGTIN) of the item to which it is affixed. This allows differentiation of identical items.

2) Interrogators (or readers)

An interrogator, or more often called a reader, is a radio frequency transmitting and receiving device used to communicate with an RFID tag. The device was named an interrogator because it "interrogates" the tags. The term "reader" is a more colloquial term, but is sometimes misleading in that many of these devices also have the ability to encode, or write information to an RFID tag. A reader basically acts as a sensor because it senses what tags are within its range and is designed to interface with an information process system, which we'll explain more about below.

3) Antennas

One or more antennas are connected to the reader and are required for the radio frequency communications between the tag and the reader. Antennas come in a variety of size and shapes and have a significant impact on read range and performance.

4) RFID Information Processing Systems

In order to obtain any tangible benefit from RFID technology, the readers must be connected to an information processing system. The information processing system provides instructions to the readers, coordinates their operation, collects output data, and most importantly, makes decisions based on business rules about the data it receives. These computer programs are sometimes called "middle-ware" or "edge-ware." We prefer to call them "Intelligent Sensor Network Platforms" because RFID readers typically need to be coordinated with other automation devices, such as:

- wireless and wired sensors: photo-eyes, motion detectors, environmental monitors, etc.

- feedback devices: light-stacks, displays, etc.

- automation control systems: triggers, servos, motors, robotics, etc.

Putting RFID Readers, Antennas, and Tags Together

An RFID read point refers to a specific antenna connected to a reader (pictured right). A read zone is a logical grouping of one or more read points (pictured left). It is important to point out that the read points comprising a read zone are NOT necessarily connected to the same reader. For example: Read Zone Alpha may be made up of Antenna 1 and 2 from Reader 5 and Antenna 3 and 4 from Reader 6.

An RFID read point refers to a specific antenna connected to a reader (pictured right). A read zone is a logical grouping of one or more read points (pictured left). It is important to point out that the read points comprising a read zone are NOT necessarily connected to the same reader. For example: Read Zone Alpha may be made up of Antenna 1 and 2 from Reader 5 and Antenna 3 and 4 from Reader 6.

The primary function of an RFID reader is to report state changes to its environment. A change in state is called an event. There are three types of RFID-related events:

1. A New Tag event occurs when a tag appears to a reader for the first time.

2. A Visibility Changed event occurs when the visibility of a tag changes for a read point.

3. A Tag Not Visible event occurs when a tag is no longer visible to any read point.

A reader captures events along with the date, time, and data from the RFID tag(s) that caused the event to occur. The real benefit is realized from the ability to make decisions based on the events reported from multiple readers. That's where the information processing systems come in. Edgeware or middleware aggregates and filters the event data coming from the readers and may even make decisions based on a defined set of rules. The software may be operating on a stand-alone computer, or an industrial appliance designed specifically for this purpose.

In addition to the four basic components (reader, tags, antennas, middleware), more sophisticated RFID systems incorporate monitoring and sensing devices such as electronic switches, photo-eyes, and motion sensors. The events from these devices are combined with the RFID related events for improved decision processing. For example: when the dock door switch is on (door is open), power on the RFID reader, and store all RFID events into the database.

RFID systems are often connected to warehouse automation systems that are made up of devices such as Program Logic Controllers (PLCs) pictured left. The events generated by the RFID system triggers these devices to perform various operations. For example: When the RFID reader reports tag 12345, illuminate a stack light

Where should RFID technology be applied?

When determining where RFID technology should be applied within a supply chain, ask, “Where can we benefit from asset visibility?†Typically, asset visibility  is desired when movement occurs (e.g., when the product comes in the dock door, when the product is shelved in the distribution center). Chances are someone in your organization asked where visibility would be useful when designing the manufacturing plants, distribution centers, and other locations across your supply chain. Most likely, these locations have some type of Automatic Identification (Auto-Id) technology already in place, such as a barcode scanner. Manual methods of identification are very common. The standard to which all other identification methods are measured is still a person with paper and clipboard counting what he sees.

is desired when movement occurs (e.g., when the product comes in the dock door, when the product is shelved in the distribution center). Chances are someone in your organization asked where visibility would be useful when designing the manufacturing plants, distribution centers, and other locations across your supply chain. Most likely, these locations have some type of Automatic Identification (Auto-Id) technology already in place, such as a barcode scanner. Manual methods of identification are very common. The standard to which all other identification methods are measured is still a person with paper and clipboard counting what he sees.

Contrary to what you may have read, RFID will not completely replace bar codes. Just as human readable information is still used in conjunction with bar codes, RFID technology will compliment barcode technology. RFID only makes sense where it provides advantages over ba codes, and there are five advantages that it has:

- Speed

An RFID reader can read tags faster than a bar code scanner can scan bar codes. RFID readers designed for supply chain operations can perform between up to 1,500 read operations per second. - Read Distance

Depending on the equipment configuration, it is not uncommon to read RFID tags at distances of 3 meters between the tag and the antenna. This area is commonly referred to as the "read field". The size and shape of the read field may be controlled by adjusting reader power settings, antenna selection, antenna placement, and other techniques. A read field is three dimensional in that its size may be measured using X, Y, and Z dimensions. - Simultaneous vs. sequential scanning

RFID readers can identify multiple tags within the read field. The most common application of this capability is for the reader to report all tags within its read field. - Non-line of sight

Depending on the frequency being used, radio waves can penetrate most materials. When using the standards being adopted for RFID in supply chain operations there are challenges when working with materials that contain liquid or metal. However, there are proven methods for working around these challenges. - Durability

RFID tags can still operate even if they get dirty. RFID tags can be hardened by encasing them in plastic. Some companies have even embedded RFID tags directly into the products they manufacture.

The more advantages that can be applied, the greater the value of using RFID over an alternative method of identification

Where are companies using RFID technology today?

There are numerous locations within a facility to apply RFID technology. We’ll focus on some of the more common industrial and retail locations and the benefits companies are realizing from improved asset visibility using RFID technology.

Industrial Locations

For the purposes of this article, the industrial locations described below are assumed to be in such places as a warehouse, a distribution center (DC), or a manufacturing plant. These facilities are common in most supply chain operations.

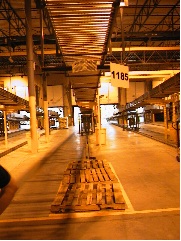

RFID-Enabled Portals

An RFID-Enabled Portal is a doorway through which goods travel. There are several configurations of portals, but the most common is the dock door. RFID technology is used at portal locations because all of the benefits described above may be realized.

As pallets and cases of RFID tagged items move through the portal, they may be rapidly identified even when traveling via materials handling equipment, such as a forklift.

Directionality calculated versus directionality assumed.

Often, it is important to know the direction in which the product is traveling. Directionality can be determined by using one of two methods: calculated or assumed.

Calculating directionality is the most accurate method to determine the path of an item. This works by comparing the outputs of two or more read points. When a tag is seen in read zone A, and then in read zone B, it can be determined that the tag is moving in the direction from A to B. This is an extremely simplistic description of a much more complicated algorithm.

Assuming directionality is the simpler of the two methods, but not always possible or accurate. For example, if a dock door is dedicated for only outbound shipping functions, then it can be assumed that when a tag is seen there, it is traveling out through the door. The problem with this assumption is that goods are often loaded, un-loaded, and re-loaded again. Assuming directionality does not take this process into account.

Inbound Receiving Doors

RFID-enabled receiving doors can provide automatic inventory updates for received goods. Retailers are using RFID for verification that the products actually received match the contents of the advanced shipping notice (ASN). By combining RFID with display terminals, operations personnel can be instructed what to do with the product just received (e.g., "place this case in the special orders pile").

Outbound Shipping Doors

The benefit to RFID-enabled outbound shipping doors is predominately in verification. Not only can RFID ensure that the goods being loaded onto the right truck, it can also verify that products are loaded in the proper sequence. This is especially important with full pallets on trailers with multiple destinations. It prevents one company from having to move another company’s product to access their own pallets.

Inter-facility Doors

Multiple facilities may be built next to each other. For example, a manufacturing plant may be located adjacent to a distribution center. Finished goods may be moved from one facility to the other. An RFID portal installed in the routes that connect these facilities can automate the transfer process.

Hybrid Doors

In smaller facilities, it is not uncommon to use dock doors for both inbound and outbound operations. For these portals, the directionality must be calculated. The addition of a manual switch can allow an operator to specify what task the door is currently serving: shipping or receiving.

Storage

This is where a trailer is used as an actual storage location. This is not very common and typically only found in facilities that are near capacity or have shipments that are seasonal. Directionality is important in that it is important to know if the products have been put in or taken out.

Overlapping read fields

The toughest challenge to RFID-enabled portals is in environments that have multiple adjacent portals. Overlapping read fields can result in multiple readers reporting the same RFID tag is present. It is important to determine what read zone the tag is closest to before load verification can be performed or an inventory update made. There are several methods that help with overlapping read fields:

Tie the RFID reader power-on/power-off to the door being opened and closed. This is the simplest and easiest method. If the portal door is closed, product is not going to be traveling through it.

Carefully configure the read field. There are methods to control the size and shape of the read field so that adjacent fields do not overlap. Unfortunately, no matter how well defined the read field, RF reflections will occur and cannot be completely eliminated. However, edge-ware or middle-ware that provides filtering capability can be used to make an intelligent assumption as to the closest read point to a tag.

Shelf or Location Antennas

Just as an item or product is tracked on its journey into the warehouse, it is equally important to know where it resides in the facility for easy retrieval and verification. Although still too expensive for most companies to implement throughout the warehouse, some companies are RFID-enabling storage locations. By using a shelf antenna for small goods or location antennas behind larger items, inventory can be automatically updated as products are picked or put-away. Not only does this create a much more real-time inventory, but it also frees operators from performing bar code scanning or manually writing product relocation tickets, which have to be keyed in later. Operators can be given instant feedback when putting goods in the wrong location, or as some advanced business models have demonstrated, products can be placed in any open location because the RFID technology instantly captures where the product is put away. Therefore, it doesn’t matter what location it’s in because you can always find it.

Mobile RFID Readers

Hand-held RFID Devices

Working with an RFID-enabled hand-held unit is not like working with a hand-held bar code scanner. An RFID hand-held unit will scan multiple RFID tags in its read field. Again, it’s performing simultaneous scanning vs. sequential scanning. Hand-held RFID readers are being used in a way that bar code scanners cannot be used: product location. When the device is placed in a ‘search’ mode, an audible tone is heard as the hand-held gets closer to tag being searched for. The closer the operator holds the hand-held scanner to the tag, the more rapidly it beeps. Because many of these units perform both bar code and RFID scanning functions, companies are opting to replace older units with newer, multifunction models.

Forklift, clamp-truck, or MHE mounted RFID reader

Instead of using shelf or location antennas, RFID readers can be mounted on to materials handling equipment (MHE) such as forklifts or clamp-trucks. By combining RFID with positional tracking of the equipment, real time visibility of moving goods can be seen. Companies know what the forklift is carrying and where it is driving. The primary goal is not only more real-time inventory control, but also a reduction of unnecessary work. System verification can ensure that anytime an operator touches a product, they’re touching the correct product, for the correct reason, at the correct time, and performing the correct action with it.

RFID Tag Commissioning Station

One of the quickest and easiest ways to get started using RFID technology is to replace a bar code printer with an RFID printer/encoder. With minimal programming, an RFID tag can be encoded with a unique identifier at the same time the label is printed. The label is hand applied to a product and voila, an RFID tagged asset is created. This technique is commonly referred to as "slap and ship." The primary drawback to this approach is that it creates a bottleneck except at very low volumes, typically 1,000 tags per day or less. Setting up an RFID printer/encoder is valuable for exception handling, such as replacement of a failed tag or a product that requires special handling.

Conveyance systems

Visibility Point

One of the advantages of RFID technology over bar codes is that it does not require a line of sight to scan. If an item is traveling on a conveyor but is not oriented properly, it will still read if the read zone is designed well. In some situations, RFID performs so much more rapidly than bar codes the speed of the conveyor may be increased for faster throughput. RFID equipment is often combined with conveyor diverters to control product flow to the correct destination.

Tag Commissioning

If the tag is already applied to an item traveling on a conveyor, an interrogator can encode the tag. This technique is used for some work-in-progress management applications. The serial number of the item is encoded on the tag at the first stage. As the tagged product goes through the assembly process, its location can be automatically determined. Depending on the RFID technology in use, products on a conveyor many to have come to a complete stop to allow time for the tag to be encoded.

Automatic Label Applicator / RFID encoder

As with bar code printers, automatic label applicators are also being outfitted with RFID technology to encode tags as the label is applied to a product. These units are being installed on manufacturing lines where slap and ship solutions cannot provide the output volume. It is important to compare the speed of the new RFID encoder/applicator to the label applicator in place. Depending on the unit being installed the manufacturing line speed may be increased.

As with bar code printers, automatic label applicators are also being outfitted with RFID technology to encode tags as the label is applied to a product. These units are being installed on manufacturing lines where slap and ship solutions cannot provide the output volume. It is important to compare the speed of the new RFID encoder/applicator to the label applicator in place. Depending on the unit being installed the manufacturing line speed may be increased.

Palletizer or Stretch Wrap Machine

An ideal location for asset visibility is where pallet loads are built. What better time to automatically verify the contents of the pallet? If there is a case that shouldn’t be included, or a product is missing, a visual or audible confirmation can be given to operations personnel that a problem exists and needs to be corrected. It’s also a great time to capture metrics, for example, how long did it take between the tag application and the pallet being completed? It’s also a good time, because the pallet is often bound for the next step in the process: staging or outbound shipping.

Staging or Holding area

Staging or holding areas are important locations for asset visibility. Knowing that a product was just received, but not yet put away can save warehouse personnel valuable time. Creating RFID enabled read locations such as inbound and outbound staging, as well as quality-hold and repair locations greatly reduce times searching for ‘missing’ products.

Retail Locations (Stores)

The back room of a retail location has a lot of commonality with the industrial locations, but there are subtle differences. The primary objective of RFID-enabled read points in a retail location is to determine in which area of the building was the product last visible. On the sales floor, a new set of RFID-enabled locations are coming that will create a new shopping experience for consumers, which we will explain more about below.

Retail locations achieve the greatest benefit from using RFID tags at the item level. Item-level tagging is already occurring for products where the item is treated as a case. For example, electronics items such as large televisions or DVD players are tagged at the item level. Club stores that sell cases of products treat the RFID-tagged case as an item. Some pharmaceutical products are also being tagged at the item or pack level (for example, a bottle of vitamins, a box of cold pills).

RFID-Enabled Portals

Dock Doors

RFID-enabled dock doors at retail locations are very similar to those in industrial locations. As the doors are most typically used for inbound receiving, directionality can be assumed. There may be a dedicated outbound trailer used for returns. During holidays, it is not uncommon to use trailers for storage of fast-moving seasonal items.

Perimeter Doors

Perimeter doors are any doors that may be used for entry to or exit from the building. Sometimes perimeter doors are used for receiving purposes. Bakery goods, parcels, and even pallets may come in through these doors. These doors are normally configured as receiving doors, but are also used for security. RFID-tagged goods should not be traveling into the read field of the perimeter door unless the products has passed through the point-of-sale system (see below). Eventually RFID tags will replace electronic article surveillance (EAS) systems. There are companies offering RFID readers that are integrated with EAS. The cost of these units is slightly more than standard EAS systems.

Other Portals

A retail store has a number of other portals inside the building that may be RFID-enabled, such as impact doors between the backroom and the retail floor. Doors between departments such as the meat department and deli, or the doors between the cold freezer and chilled icebox can also be RFID-enabled. These portals must be carefully designed due to the variety of ways product may be traveling through them. For example a case may be hand-carried, or carried on a push cart or in a shopping cart. Directionality is very important for these portals and cannot be assumed. The objective of these portals is to determine where the products are stocked.

Mobile RFID Read Points

Hand-held

Hand-held RFID readers are useful for performing inventory spot check either on the sales floor or in the back room. As with an industrial location, locating items in a given area reduces time spent searching for the items.

Back Room Locations

Conveyance Systems

A conveyance system in the backroom of a retail location is typically used to more rapidly off-load loose cases of goods from a truck. The cases are hand pushed from the receiving area into another section of backroom. Here, store personnel either place the cases on a cart to be moved to sales floor, or stocked on a shelf in the backroom.

Baler / Trash Compactor

After the items have been removed from a case and placed on the shelf, the case is typically discarded. This is an end-of-product-life event and should be captured. By RFID-enabling the baler and trash compactor, retailers can automatically update inventory when a case is seen. Additionally, it provides an added layer of security against employee theft. If an RFID tagged item is discarded prematurely, then an alert can be generated.

Sales Floor

RFID-enabled shelf units and displays

RFID-enabled shelves and display units currently carry a high price tag, but they provide retailers and consumers with abilities that have never existed before. The primary benefit to retailers is inventory control and automatic alerts. Alerts automatically notify store personnel when an item is placed in the wrong location so that it may be put back where it belongs. This results in faster replenishment of goods and fewer out-of-stocks.

Clothing and apparel companies especially benefit from RFID because it is very labor intensive to ensure all of the available sizes, colors, or other variations are on the sales floor. Even though the display may be filled with products, an alert is generated when a particular size is out of stock. Consumers benefit because their favorite product or their specific size is on the shelf.

For date-sensitive inventory (DSI), an automatic notification can be generated when goods expire. Store personnel can proactively restock with fresh product. This ensures consumers will not purchase expired goods.

Yet another benefit is security. For items that are frequently stolen, special displays can be made. One manufacturer built a display unit that includes a digital camera. If more than three items we removed in under 1 second, then the camera took a picture of the customer and notified security. The retailer can then ensure that the items are processed by the point-of-sale.

Sales Floor Hotspots

Taking the RFID-enabled shelf and display to the next level, retailers are developing specific locations or “hot spots†where consumers can bring RFID tagged products and obtain information about the product. When an RFID tag is read, a monitor next to the hotspot displays information about the product the customer has in hand. The customer can check stock levels, go to the product website, find accessories, special order a different color, or any other action the retailer chooses. The potential applications are limitless. One such hotspot is called a “Magic Mirrorâ€. An RFID reader and a monitor are placed behind a mirror and are automatically activated when an RFID tag comes into the read field. To the customer, a virtual attendant behind the mirror appears to be speaking about the product.

Dressing Room

A Magic Mirror is very useful in a dressing room. If combined with a touch screen, a customer can automatically request that a live attendant bring a different size of the item being tried. This is a real convenience for the consumer and retailers benefit from the added security of knowing exactly what items are in the dressing rooms. Automatic alerts can be generated to restock items that a customer leaves in the dressing room.

Point-of-Sale (POS)

Anyone that has ever worked a retail checkout will attest that bar codes do not scan. An unusually shaped of an item (like on a bag of bread rolls from a bakery), or water or dirt on the tag, all prevent bar codes from scanning. This forces manual entry of the product number, which is time-consuming and prone to error. As described earlier, the benefits of RFID will improve the point-of-sale accuracy. Retailers believe that the added ease of scanning will increase customer acceptance to use self-check-out lines instead of cashier attended ones. The addition of having specific serial on every item provides countless benefits, of which a few were mentioned above.

Customer Service Desk

With serial numbers included on the RFID tag of every item sold, retailers can be sure that the item being returned is indeed the exact item that was purchased. What’s of added benefit is the retailer knows exactly what price the customer paid even if the customer doesn’t have their receipt. It is also useful for warranties, rebates, and keeping services history.

Some of the Benefits of RFID-Enabled Visibility Points

![]() Lower labor rates: The process of manual bar code scanning is time consuming. Receiving a truck load of loose cases can take a single operator with a hand-held bar code scanner up to 40 hours to check in. Using RFID enabled portals reduces the time to just a few hours.

Lower labor rates: The process of manual bar code scanning is time consuming. Receiving a truck load of loose cases can take a single operator with a hand-held bar code scanner up to 40 hours to check in. Using RFID enabled portals reduces the time to just a few hours.

When moving products between locations, such as from a holding area to outbound shipping or from a stock room to the sales floor, most relocation processes include a step where personnel scan a one or more bar codes to capture that movement has taken place. RFID makes this process automatic simply by capturing where products are last seen.

Reduced errors: By design, RFID tags that contain EPCs (Electronic Product Codes) are serialized whereby UPC (Universal Product Codes) bar codes are not. If the same UPC is scanned twice, it is counted twice. If the same RFID tag is read twice or more, it is only counted once. This greatly reduces the costly inaccuracies in inventory counts caused by improper bar code scanning.

Improved Data: When moving from manual bar code-based processes to RFID-enabled processes, the data feeds switch from batch processing to real time. This has been proven to allow pro-active decisions based on movement versus re-active decisions. Gillette published a study showing that stores using RFID to move products from the backroom to the sales floor shelf before a promotion started yielded 48% higher sales compared to stores not using RFID. Additionally, having real-time visibility helps improve handling of time sensitive products, such as products with expiration dates.

RFID-enabled visibility points have a tremendous impact on efficiency. For retail stores using RFID, Wal-Mart has reported a reduction in out of stocks by 30% compared to the previous process that was based on bar code scanning using a hand-held device. This alone equates to billions of dollars in savings to the world’s largest retailer and its’ suppliers.

Final Thoughts

New and exciting applications for RFID technology are being realized every day. This article is meant to provide only a glimpse into how companies are currently applying the technology. Every company has its unique processes and systems. It is important to be creative when designing an RFID system. If you do, the potential can be great.