Depeche Mode is French for 'fast fashion' and it's extremely accurate. In the retail fashion industry, success is based on the ability to put the latest style in the correct size in the customer’s hand at the right time. Although it sounds simple, it's more difficult to do than you'd expect. In this video, Louis Sirico travels from San Francisco to Hong Kong to Paris to show you how RFID technology benefits the retail apparel industry.

The Business Challenge For Retail Apparel

Apparel is a perishable commodity where trends change overnight, making it difficult to ultimately predict duration and demand. Ordering too much product translates into increased capital expenses that can erode a retailer’s bottom line, while ordering too little can lead to missed opportunities and lost sales. Unlike other retail segments where items have a set location on the shelves, items do not stay in one spot. Inventory is constantly on the move between the rack and the dressing room throughout the day, often causing a false out-of-stock situation and a lost sale when the size a customer may need is in the dressing room waiting to be re-stocked. And keeping an accurate inventory is difficult — and costly — further compounding the ability to ensure the right item is available for your customers at the point of decision.

The financial impact associated with these challenges is staggering to apparel retailers. The Harvard Business School found that eight percent of all retail items are out-of-stock at any given time, costing the top 100 retailers an estimated $69 billion annually. Lack of inventory visibility often results in up to 65 percent inaccuracy in inventory counting, making accurate ordering an even more difficult task. And the very nature of high-value merchandise that is openly accessible to customers increases the opportunities for theft.

How RFID Technology Benefits Retail Apparel Companies

The world’s top retail companies are using RFID because of the big benefits the technology brings, including:

- Reduced time to take inventory

- Improvements in inventory accuracy

- An enhanced customer shopping experience

Reduced Time to Take Inventory

The right technology can help fashion retailers address these age-old issues. By deploying RFID, apparel retailers can achieve the real-time inventory visibility required to improve the many aspects of inventory management — with very little effort. For example, a complete manual cycle count may often take days — but an employee equipped with a handheld RFID reader or a mobile RFID reader on a cart can take a complete inventory in minutes. In a market characterized by seasonal products with a short shelf life, real-time inventory visibility can create a real business advantage. Ordering is improved through the ‘right now’ ability to see what is truly in stock, enabling a more rapid reaction to inventory demand and stocking levels. High levels of ‘safety stock’ — excess inventory ordered to protect against out-of-stocks — can be reduced or eliminated. Lost sales due to the inability to locate inventory are eliminated since even items in dressing rooms are visible. Since each product in a specific shipment has a unique identifier, quality assurance and counterfeit prevention are enhanced — improved accuracy in picking and packing operations translates into the proper fulfillment of purchase orders. Imitation products are easy to spot. Missing shipments that can impact the assortment on your shelves are quickly identified. And the new level of inventory visibility improves loss prevention measures by providing an additional layer of intelligence to existing, proven technologies such as Electronic Article Surveillance (EAS).

Point of manufacture to point of sale – design to destination/rack

The benefits of using RFID for retail apparel

|

Several specialty apparel retailers have deployed successful pilot and first-stage

implementations of RFID applications,

|

While consumer packaged goods (CPG) RFID applications began with pallet and case tagging to improve supply chain visibility, industry experts believe that apparel retailers can realize the largest and immediate returns by moving straight to item level tagging with a customer-facing focus. RFID tags applied to each item at the point of manufacture enable the automated and granular tracking of each item from creation to purchase.

As a result, orders are easily tracked all the way through the supply chain, order processing at the distribution level is more efficient, counterfeit goods inserted anywhere in the supply chain are easy to identify, and granular visibility of items in the retail store ensure that the right item is available at the right time to increase sales — and protect profitability.

A Large French Retail Group

As the world’s second largest retailer and the top European retailer, this retail group has over 15,000 company-owned and franchised stores in 31 countries. It has found significant value using RFID for apparel tracking or, as it’s referred to in Europe, RFID solutions for the textile supply chain.

This retail group used EPC/RFID technology with apparel and books. Their primary goals for textile tracking include:

This retail group used EPC/RFID technology with apparel and books. Their primary goals for textile tracking include:

- Improve supply chain execution

- Use the global visibility to improve stock management

- Assess the visibility of follow-up of products within the store

RFID Apparel Project Overview

Neopost ID implemented RFID technology throughout the retailer’s supply chain: from source tagging at the manufacturer in China, through the distribution centers in France, to a first selected store in Europe. The initial project includes 12,000 RFID-tagged apparel articles in store.

The Retailer’s Textile Supply Chain |

|

|

|

Eliminating Shrink that isn’t Shrink

One of the first discoveries the retailer made after implementing RFID was they were receiving goods they didn’t order. For example, the store would order quantity 100 of the size L of a particular garment, but actually received 100 sizes M. Because stock management was based on monthly manual inventory and order details alone, their inventory system assumed they received what was ordered. They didn’t have the labor to verify receipts manually. Their inventory system would report 100 size L in stock, when in reality they were under stocked in L and overstocked in M. Knowing what was actually received solved serious shrinkage problems because they had wrong numbers to start with – it was not theft.

At picking in the DC, there is an RFID-enabled table for verification, as well as a portal at shipping that verifies that the expected number of tags on the pallet match the actual number.Â

At picking in the DC, there is an RFID-enabled table for verification, as well as a portal at shipping that verifies that the expected number of tags on the pallet match the actual number.Â

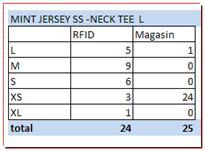

Improvements in Inventory Accuracy

Although the total item counts were close to accurate, the accuracy for style, sizes and colors were not actually close to reality. If there was a pile of clothes, the inventory control person would normally count only the top item, so if the size was different below, a variance in inventory would be created. The example (pictured right) demonstrates this. (Please note, "Magasin" is French for "Store".)

Although the total item counts were close to accurate, the accuracy for style, sizes and colors were not actually close to reality. If there was a pile of clothes, the inventory control person would normally count only the top item, so if the size was different below, a variance in inventory would be created. The example (pictured right) demonstrates this. (Please note, "Magasin" is French for "Store".)

Before RFID, they had 50% inventory accuracy. Now with RFID they are achieving 99% accuracy. The only reason it’s less than 100% is due to some items not being tagged correctly. The benefit to the customer has been increasing over time.

Measured  Savings in Inventory Labor Time

Savings in Inventory Labor Time

The staff is far more comfortable using RFID technology and the store is now measuring employee performance using RFID. Before RFID, it took an average of 50 hours to perform a manual inventory. That was reduced to 2 hours for inventory when the implementation started. Today, it takes approximately 45 minutes for inventory. That’s a productivity gain between 80-92% depending on staff experience level.

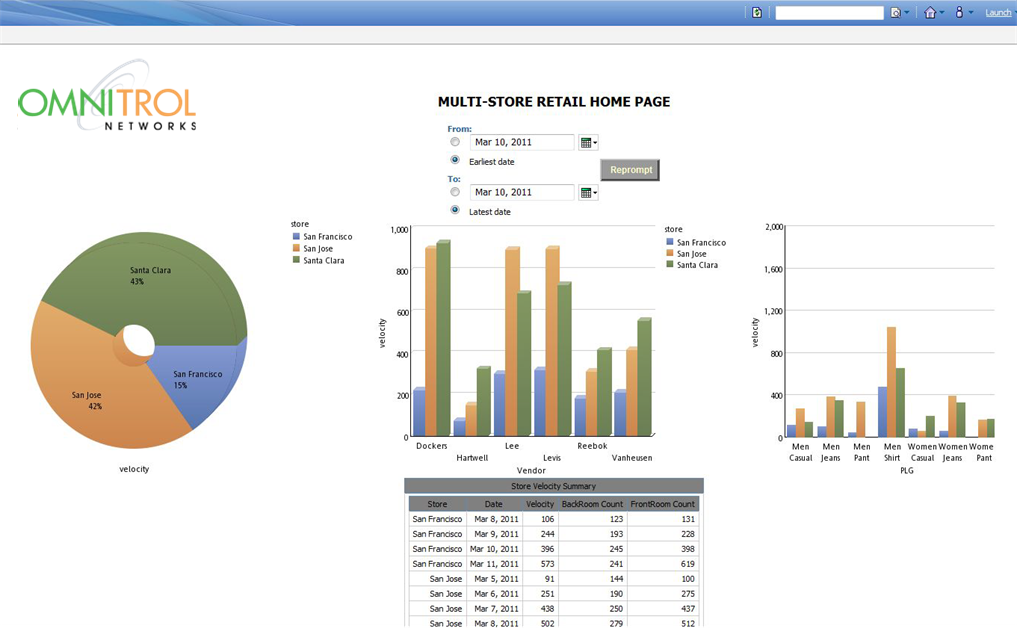

The Benefits Multiply Across Stores

As RFID technology improves inventory accuracy at each store, the results start to become visible at a higher level (see image below). Retailers are able to apply predictive analytics to determine the estimated date to zero (ETZ) inventory for each individual item or SKU. This allows them to proactively order a particular style, size, or color of an apparel item before it goes out of stock. It also allows a transfer when one location has too many and another location that doesn't have enough. These capabilities were only dreamed about by retailers prior to implementing RFID.

RFID Creates an Enhanced Customer Shopping Experience

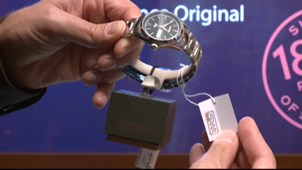

This may look like an ordinary jewelry display, but it’s actually been enhanced with RFID technology. Inside the display case there is a very thin antenna connected to an RFID reader. All of the items in the display case have an RFID tag affixed to the price tag (See photo below left). These enhancements provide enormous benefits to retailers.

First, the system performs inventory in real-time. As soon as an item is added, or removed, from the display case - inventory is automatically updated. Plus, retailers can see which items customers are most interested in based on how often it goes in and out of the case. This is incredibly useful information that could not be easily obtained before.

First, the system performs inventory in real-time. As soon as an item is added, or removed, from the display case - inventory is automatically updated. Plus, retailers can see which items customers are most interested in based on how often it goes in and out of the case. This is incredibly useful information that could not be easily obtained before.

RFID also enhances security. The system is combined with the store’s video surveillance system and automatically captures the exact time an item is moved. In the event that an item can’t be found, security personnel can go directly to the exact time in the security video the product was moved. This saves hundreds or even thousands of hours reviewing video footage.

The customer’s shopping experience is also enhanced. For example, when an item is placed on this RFID-enhanced display tray, all of the complimentary accessories automatically appear.

After the customer purchases the product and removes the price tag, the RFID is also removed.

How the RFID Enabled Jewelry Display Works

The thin antenna we spoke of is the thinnest UHF antenna on the market. It’s extremely durable and can be placed directly on wood, metal, or any surface. That means that existing displays, shelves, and furniture do not have to be retrofitted to accommodate bulky antennas. The thin antenna also provides extremely controlled RFID reads, which prevents reading tags in adjacent read zones.

The RFID reader used supports up to 16 separate antennas, more than any other RFID reader in its class. That means that one reader can power 16 different displays, shelves, or even an RFID-enhanced Point-of-sale counter.

Software coordinates the RFID readers and provides the business logic for real-time inventory tracking and reporting without any need to integrate or customize back-end systems. It can also scale to support hundreds of retail stores and distribution centers and provide predictive analytics that can reduce out-of-stocks

Experts Agree There is Strong Success for RFID in Retail Apparel

“RFID’s use in the apparel sector represents the greatest near-term opportunity for business improvements and fewest impediments to growth in the retail industry,” says RFID analyst Michael J. Liard. “A quick, demonstrable ROI and key business metrics for adoption have been clearly established and the results of nearly all evaluations conducted have been compelling. As a result, market activity is brisk and promising, especially among early-adopter specialty apparel retailers.”

Prior to filing for bankruptcy protect, American Apparel operated 260 stores and generated sales of more than $600 million. An analysis of American Apparel suggests the per-store payback for a 260 store RFID rollout is about 4.5 months given increased sales from fewer out-of-stocks and reduced labor. The strong return on investment is a result of increased revenue per store of 14% compared to non-RFID stores, and a labor savings of just under 190 hours per month. RFID boosted revenue by providing improved inventory visibility and automation that enabled process changes to ensure a full complement of product offerings were available on the retail floor at all times. This was accomplished with reduced labor for weekly cycle counts and inventory searches. The complete American Apparel Case Study Write-up and Analysis is available here.

The following case studies illustrate how retail apparel companies can significantly increase sales by deploying RFID solutions.

Case study #1: National Department Store

|

Case study #2: Global Specialty Store

|

| Annual Sales:......................................... $3.47B Number of Retail Outlets:............................. 68 Misplaced Goods/Out-of-Stocks:....... 5 percent |

Avg. Annual Sales:...$770M per store/61.6B total Number of Retail Outlets:................................. 80 Misplaced Goods/Out-of-Stocks:......16.4 percent |

A national department store sought to reduce the high costs associated with out-of-stock and misplaced items. RFID was implemented to automate the inventory process and enable regular yet cost-efficient inventory taking that significantly improved inventory management, enabling the retail apparel company to increase inventory availability for customers — and improve sales. With RFID, inventory on shelves was readily visible, ensuring prompt restocking. Inventory throughout the store— from the fitting room to the back room — was also visible, reducing stockouts and lost sales due to the inability to locate an in-stock item. Net results from deploying RFID:

|

A global specialty store identified that the high rate of misplaced goods and out-of-stocks had a significant impact on profitability. Additionally, a slow labor intensive receiving process resulted in less than timely replenishment of inventory on the store floor — and lost sales opportunities. To reduce the losses, the chain needed a better view of inventory to support better and more agile decision-making in the ordering process as well as provide the ability to locate a specific item in the store — regardless of where it might be located. Known for their service, the small staff in the boutique-style stores needed to remain focused on helping customers— not counting inventory. While adding staff would enable more frequent and thorough inventory taking and a more rapid receiving process, the additional costs would threaten current profitability levels. The customer sought to improve the efficiency of day-to-day business operations in order to allow the current staff to handle more tasks throughout the day — without impacting customer service levels. The answer was the powerful automation of an RFID solution. With RFID, the existing staff could simply wheel a cart equipped with a mobile reader throughout the storefront and fitting room areas to obtain a real-time view of inventory in minutes. An RFID handheld reader enables the rapid location of an item that is in stock but not on the rack. And the ability to automatically identify and reconcile

|

Location 1) Source tagging in China

Location 1) Source tagging in China Location 2) At the Distribution Center (DC) in France and Supplier’s Warehouse

Location 2) At the Distribution Center (DC) in France and Supplier’s Warehouse Location 3) Retail Store in Europe, backroom and store floor

Location 3) Retail Store in Europe, backroom and store floor